Current location: Home»CHEMSHUN News » Customer Center » Chemshun Vedios » How To Install Alumina Ceramic Welding Tile Liner

Top articles

- Alumina ceramic pipe Production

- Ceramic Composite Pipe Installation

- Rubber Ceramic Plate for Convey System

- Happy Chinese Tiger Year 2022

- Mining Ceramic Grinding Balls Media

- Alumina Ceramic Catalyst Carrier

- Silicon Carbide Anti-Wear Ceramics

- Silicon Carbide Ceramics (SSIC Series)

- Al2O3 99.7% Large Size Fine Ceramics

- Chemshun Ceramics--Workshop Product Show In May

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

How To Install Alumina Ceramic Welding Tile Liner

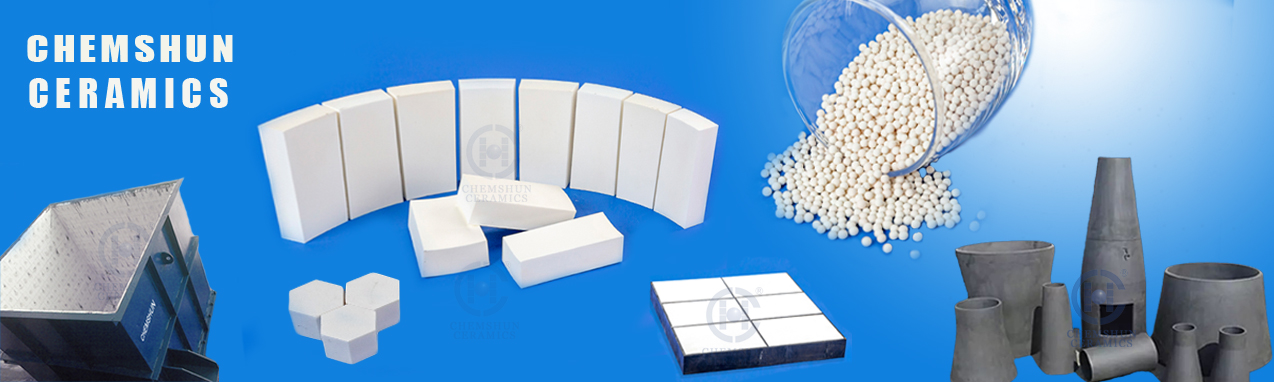

CHEMSHUN CERAMICS

The Wear Resistant Ceramic Manufacturer

Install Alumina Ceramic Welding Tile Liner need:

1: Materials Prepared , Like New Steel Plate, Ceramic Tile, Correctly Mixed Epoxy Resin, Hammer and Others.

2: Apply Mixed Epoxy Resin On The Both End Of Ceramic Tiles And Surface Of Steel Plate.

3: Fastened The Ceramic Tiles On The Steel Plate Carefully .

Chemshun Ceramics Accept All Kinds of Alumina Ceramics Design And Installation On Site For Bulk Material Handling System.

Previous page:How To Choose Chute LiningNext

page: Alumina Ceramic Hex Mat Installation