Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

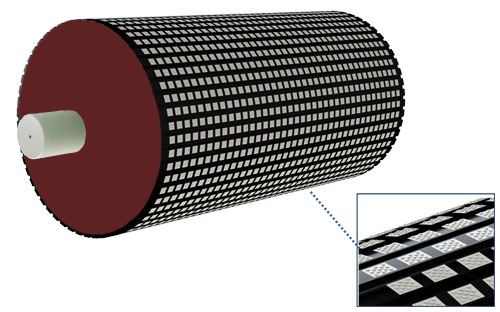

The Benefits of Ceramic Pulley Lagging

Ceramic Pulley lagging increases the traction between the belt and the pulley, which in turn reduces load and wear on the drive, belt, pulleys, bearings and take-up. Lagged in shop or in place on system. For efficient and economical conveyor operation, proper pulley lagging is integral detail – one that delivers the following key benefits:

1. Extends the life – of key conveyor components.

2. Reduces wear – from abrasive materials.

3. Prevents belt slippage – by increasing the coefficient of friction between the conveyor belt and the pulley.

4. Creates a self-cleaning action – on the pulley surface and prevents the buildup of transported bulk material, water, snow or ice.

Pingxiang Chemshun ceramics Co.Ltd. as a company which is well-known throughout the country has been committed to specializes in producing ceramic pulley lagging, and provides wear protection and install service. The company’s products including: wear resistant ceramic lining, rubber ceramic wear plate, alumina ceramic pipes, ZTA ceramics, ceramic grinding media for mining and mineral ore etc. Once you need more information welcome to contact with us by email office@chemshun.com or calling us +86-799-6790781.

Information about "rubber ceramic liner Ceramic Pulley lagging ceramic wear plate alumina ceramic lining "

- Mining machinery wear damage

- Mining machinery abrasion damage Analysis and wear protection way

- Wear resistant ceramics pipe is the best choice of fluid transportation piping

- wear resistant ceramic property in dry tribology