Top articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

Your browsing history

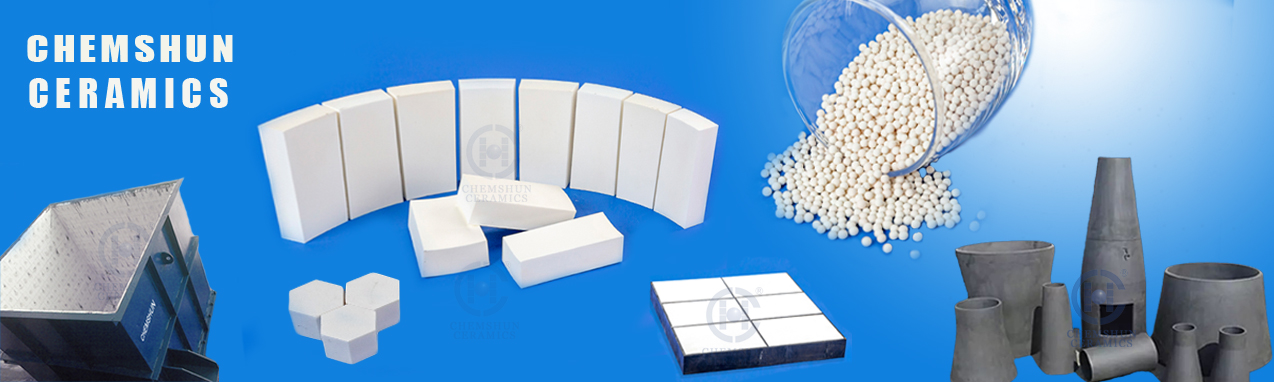

corrision and wear resistant ceramic pipe tile reduce pipeline project cost

Alumina ceramic pipe tile liner is pasted in the steel pipe wall with high temperature resistant adhesive epoxy resin glue ,then forming a solid anti-wear layer by heating after curing. The kinds

of products production process is relatively simple, short production cycle, relatively low cost.

Wear resistant pipe tile liner main Features including :

1) Good wear: ceramic layer in wear-resistant ceramic tile lined elbow pipe is abrasion Ceramics, its hardness (HRA) ≥84, the wear resistance is more than 10 times of high chromium alloy cast iron pipe fittings. the actual wear life of 5mm thick ceramic linings layer will be equivalent to 50mm thick wear-resistant steel.

2) Corrosion resistance: wear-resistant ceramic material with excellent corrosion resistance, acid, alkali, salt and a halogen salt corrosion properties.

3) High temperature performance: wear resistant ceramics itself has more than 1200 degrees Celsius temperature capability, and wear-resistant ceramic tubes can be long-term operation in the -50 ℃ to 400 ℃ umidity range after rational design and different process,, particularly suitable for high temperature burners and other equipment lining.

4) Reduce project cost: wear resistant ceramics pipe liner is mainly used for conveying particle , fluids materials and corrosive media .mainly used to replace expensive stainless steel, high chrome cast steel pipe, wear-resistant alloy tube,which can directly reduce pipeline project costs, while extending the service life. with characters of cost-effective, saving maintenance and replacement costs

Chemshun offer kinds of alumina ceramic pipe tile liner with many standard sizes , also customized size acceptable, welcome to share with you abrasion problem , office@chemshun.com

Information about "wear resistant ceramics alumina ceramic pipe ceramic linings "

- Wear resistant ceramics is widely applied in steel industry

- Chemshun Ceramics Badminton Game

- Mining machinery wear damage

- Effective strategy to reduce mining machinery wear damage

- Mining machinery abrasion damage Analysis and wear protection way

- Abrasion Damage Factors For Material Handling ceramic lined elbow pipe

- Wear resistant ceramic lined elbow pipe installation method

- Enterprise product exhibition hall Pingxiang Chemshun 2016

- The end of the global diversified miner?

- Congratulate to Pingxiang Chemshun Ceramics on being certified as the R&D Base of the Chinese National Experiment and Research Institute of Wear-Resistant Materials.