Top articles

- Welcome to EXPOMIN 2025

- Chemshun Ceramics Chinese New Year Holiday Notice

- Chemshun Ceramics wishes you a Merry Christmas

- Chemshun Chinese New Year Holidays Notice

- Chemshun Hold the Fifth Fun Games on October 21, 2023

- Participate in the PERUMIN 36rd Mining Convention Extemin 2023

- A Kiln Ignition Ceremony Was Held at The Chemshun New Factory

- Chemshun Organized Employees to Plant Trees in The New Factory Perimeter

- Chemshun Conference of 2022 Summary Commendation & 2023 Work Started

- Autumn crisp, Chemshun Ceramics Held the Fourth Fun Sports Games

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

Why choose the wear resistant ceramic as the lining of pipe and elbows of thermal power plant?

Thermal power plant coal transporting pipeline required the pipes and elbows with the characters of wear-resisting, leakproof, anti-corrosion, high temperature resistance. Preventing wear and abrasion resistance is extremely serious important.

Choosing a wear abrasion high temperature and corrosion resistant material as the straight and elbows of thermal power plant is the first task of the engineers and bosses of the power plant factories. The material developed from the steel industry to industrial plastic, change lots of for the world factories and dairy life. Now we’re meeting the advanced ceramic era. The high alumina wear resistant ceramic with the excellent characters are widely used in all kind of industrial wear application instead of the steel linings.

Why choose the high alumina wear resistant ceramic as the lining of pipe and elbows of thermal power plant?

Wear-resistant alumina ceramics' main raw material is α-Al2O3, firing at 1530-1700℃. The Rockwell hardness of HRA80-90, the wear resistance ability is equivalent to 266 times of manganese steel, and 171.5 times of high chromium cast iron, so can greatly extend the service life of the pulverized coal pipe elbow.

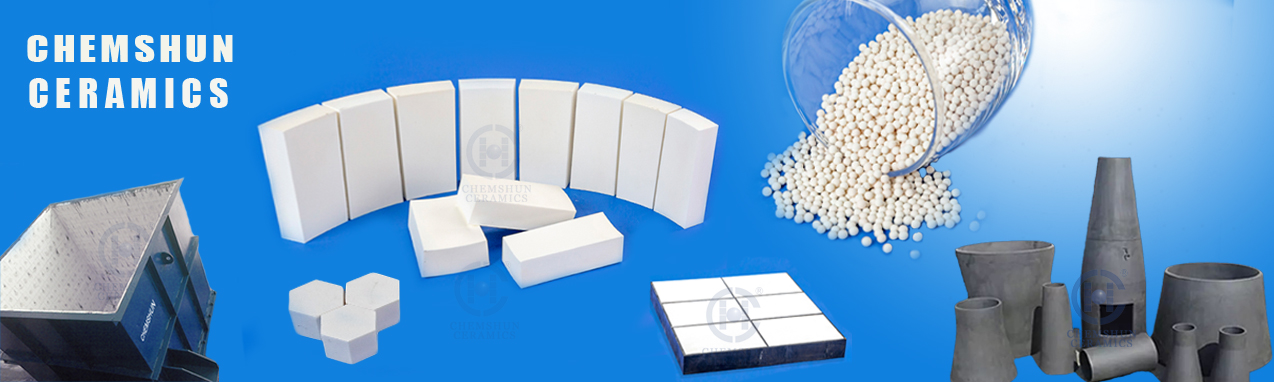

According to the pipe or elbows different size and shape, Chemshun Ceramics suggest engineers choose the trapezoidal alumina ceramic plate, or the weldable ceramic plate, or ceramic arc plate/tile, or alumina ceramic pipe. The ceramic lining pipe is easy to fix. It protects your pipes and elbows very well.