Top articles

- What is zirconia-alumina composite toughened ceramic(ZTA)?

- The application fields of alumina ceramic lining pipes

- What factors affect the high temperature resistance of wear-resistant ceramics?

- How to install ceramic rings on integrally formed wear-resistant ceramic tubes?

- Advantages of rubber ceramic composite wear plate

- What are the types of wear-resistant ceramic pipes?

- Alumina Ceramic Substrates: The Invisible Backbone of Modern Industry

- 99% Alumina Ceramic: The Superior Choice for Bulletproof Armor Materials

- Analysis of the Characteristics of Rubber Ceramic Composite Liners

- Excellent Ceramic Material—ZTA Toughened Alumina Ceramic

Latest articles

- What is zirconia-alumina composite toughened ceramic(ZTA)?

- The application fields of alumina ceramic lining pipes

- What factors affect the high temperature resistance of wear-resistant ceramics?

- How to install ceramic rings on integrally formed wear-resistant ceramic tubes?

- Advantages of rubber ceramic composite wear plate

- What are the types of wear-resistant ceramic pipes?

- Why 99% alumina ceramics are the preferred material for bulletproof armor

- Alumina Ceramic Substrates: The Invisible Backbone of Modern Industry

- Chemshun High-Performance Ceramic Substrate Production Line Kiln Officially Ignited and Put into Operation!

- 99% Alumina Ceramic: The Superior Choice for Bulletproof Armor Materials

Your browsing history

What is zirconia-alumina composite toughened ceramic(ZTA)?

In the vast field of materials science, ceramic materials have always held an important position due to their unique properties, such as high hardness, high wear resistance, and good chemical stability. However, the brittleness of traditional ceramic materials has limited their application in many fields. To overcome this defect, scientists have been constantly exploring and innovating, and ZTA zirconia-alumina composite toughened ceramics have emerged as a shining new star in the field of advanced materials.

I. Main Components of ZTA Ceramics

ZTA zirconia-alumina composite toughened ceramics mainly consist of Al2O3 and ZrO2, and also contain small amounts of Cr2O3, TiO2, and ZnO, etc. These substances have similar crystal lattices and form solid solutions with Al2O3 during sintering, playing a crucial role. They can refine grains, promote sintering, and thereby enhance the fracture toughness of the ceramics.

II. Outstanding Performance Features

High Hardness: The Rockwell hardness of ZTA zirconia-alumina composite toughened ceramics is greater than or equal to 90. This enables it to maintain its integrity even when subjected to friction and impact from various high-hardness substances, and makes it less prone to scratching or wear.

Superior wear resistance: Thanks to its unique composition and toughening mechanism, the wear volume of ZTA ceramics is less than 0.01. In long-term and high-intensity wear conditions, it can maintain stable performance, significantly extending the service life of related equipment and reducing maintenance costs.

Excellent impact resistance: Through the synergistic effect of multiple toughening methods, ZTA ceramics can effectively resist large impact forces and are not prone to breaking. They perform exceptionally well in applications that require withstanding impact loads.

Corrosion resistance: In an acidic or alkaline environment with pH values ranging from 3 to 12, ZTA ceramics can maintain stable chemical properties and are not corroded. This makes it have broad application prospects in industries such as chemical engineering, food, and medicine, which have high requirements for corrosion resistance.

Excellent stability: The shape is regular and smooth. Under various environmental conditions such as different temperatures and humidity, it can maintain stable physical and chemical properties, providing a reliable guarantee for its application in various complex environments.

Higher strength: Its flexural strength ranges from 300 to 800 MPa, and its compressive strength can reach 1200 - 3000 MPa. It can withstand significant external forces and meets the strength requirements of numerous engineering fields.

III. Application

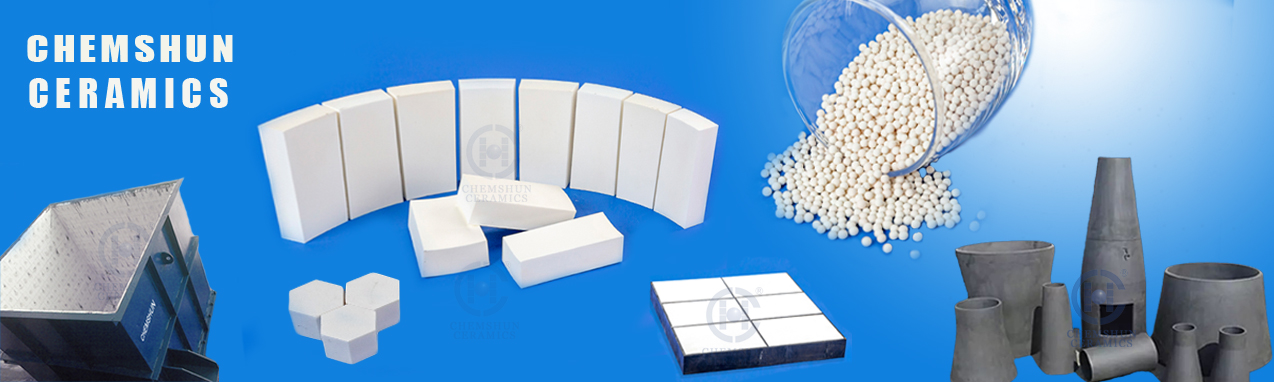

Industrial Wear Resistance Field: Due to its excellent wear resistance and impact resistance properties, ZTA zirconia-alumina composite ceramic wear-resistant lining bricks are widely used in heavy-wear equipment with large material handling volume and high impact force, such as mining machinery, metallurgical equipment, and coal conveying systems in the power industry. As an anti-wear inner lining, they effectively reduce equipment wear and improve equipment operational efficiency.

Grinding field: ZTA zirconia-alumina composite balls, as a high-performance composite abrasive material, play a crucial role in various grinding processes in multiple industries. For example: the grinding of pigments and dyes in the coating and ink industry, the mining and industrial ceramic powder material preparation industry, the grinding media for chemical and mining equipment, etc.

Protection field: Alumina bulletproof ceramic plates, partially made of ZTA ceramic material, can be customized into various shapes such as square, hexagonal, arc-shaped, spherical, and irregular pieces according to customer requirements. They have high hardness, small size tolerance, moderate density, and strong bulletproof capabilities. They are mainly used for protection of humans, vehicles, armors, building shelters, etc., providing reliable security protection.