Top articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

Your browsing history

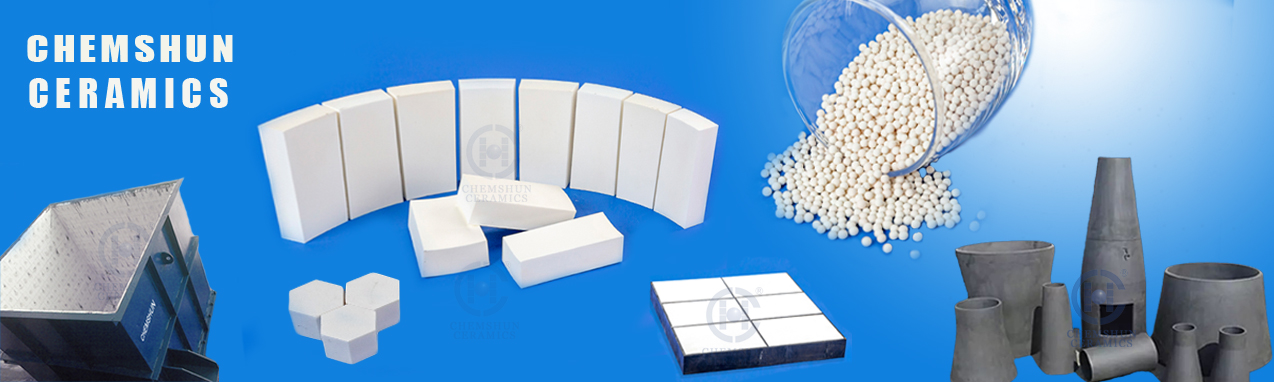

Good abrasion resistant choice for coal handling system

Chemshun ceramics offer many kinds of abrasionresistant lining for wear protection,like standard ceramic tile and engineering ceramics . Standard tiles is in the form of plain tile , welded tile , cone tile , pipe tile . Alumina weldable tiles liner can be applied by means of plug welding , the alumina tile has a hole in the center which a steel concave ferrel is inserted in the hole and welding takes place through the steel ferrel to weld to steel casing , this hole is then plugged with a alumina button , weld-on tile liner is perfectly fit for high temperature environment and high-speed operation equipment .

Coal handling system is typical case with equipment suffering kinds of abrasion damage. Frequent equipment maintenance and downtime will cause heavy cost . So welded tile liner can be perfectly installed for abrasion resistant . The equipment lined alumina ceramic abrasionresistant lining includes : chute , hopper , bunker, pipeline , cyclone separator, Chain conveyors,ball mill etc.

Chemshun Ceramics ® as wear resistant ceramic manufacturer, we supply welded abrasion resistant lining with standard sizes and engineered sizes .

Alumina ceramic weldable tile popular Sizes (Length*width*thickness ) |

100*100*20mm (4”x4”x3/4”) |

150*100*13mm (6”x4”x1/2”) |

150*100*15mm (6”x4”x5/8”) |

150*100*20mm (6”x4”x3/4”) |

150*100*25mm (6”x4”x1”) |

150*100*50mm (6”x4”x2”) |

150*50*25mm (6”x4”x1”) |

100*75*25mm (4”x3”x1”) |

120*80*20mm |

228*114*25mm |

114*114*25mm |

More sizes and customized size acceptable. Chemshun ceramics afford the relative weldable steel cone and ceramic rod. |

Dove-tail tile , engineered welded tile , standard sizes weld-on tile can be chosen for more material handling system . Welcome to consult us by mail : office@chemshun.com