Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

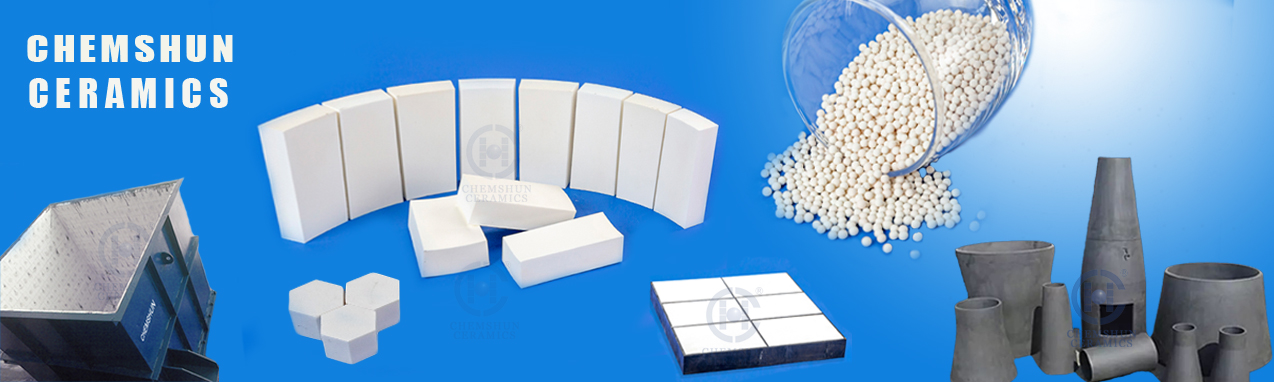

Alumina Ceramic Lining Provides Reliable Protection for Industrial Production

Alumina ceramic lining plays an important role in the industrial field. It has the characteristics of high temperature resistance, corrosion resistance, wear resistance and so on, so it is widely used in electric power, steel, metallurgy, cement and other industrial fields.

Alumina ceramic liner is made of aluminum oxide as the main raw material, which is formed and sintered at high temperature, and has excellent characteristics and advantages. First of all, it has good chemical stability, can resist acid, alkali and other corrosive media erosion; Secondly, alumina ceramic liner has the characteristics of high temperature resistance, generally can withstand temperature of about 1000℃, can maintain stability and integrity in high temperature environment; In addition, alumina ceramics also have good insulation properties, wear resistance and mechanical strength, so that it is widely used in industrial production.

Alumina ceramic liner is widely used in electric power, steel, metallurgy, cement and other industrial fields. In the power industry, it is often used in the boiler lining and chimney wall of thermal power plants, etc., because of its high temperature resistance and wear resistance, it can effectively prevent the high-temperature flue gas inside the boiler from damaging the equipment; In the steel industry, alumina ceramic lining plate is often used in the lining of the bin hopper, which can resist the wear of the material and extend the service life of the equipment; In addition, it can also be used as an acid-resistant reactor liner, which is widely used in the chemical industry.

With the development of modern industry, the demand for wear-resistant, high-temperature and corrosion-resistant materials is increasing. As a kind of high-performance ceramic material, alumina ceramic liner is expected to play a greater role in the future, providing a more reliable guarantee for industrial production.